We already know the adverse outcomes of unsafe food and how that can affect our customers and our business, so when it comes to a common source of contamination in food facilities, we ask the question –

How do we improve hand hygiene compliance even when no one is watching?

Studies have shown that contaminated hands can transfer viruses and bacteria to 5 more surfaces and up to 14 other subjects.

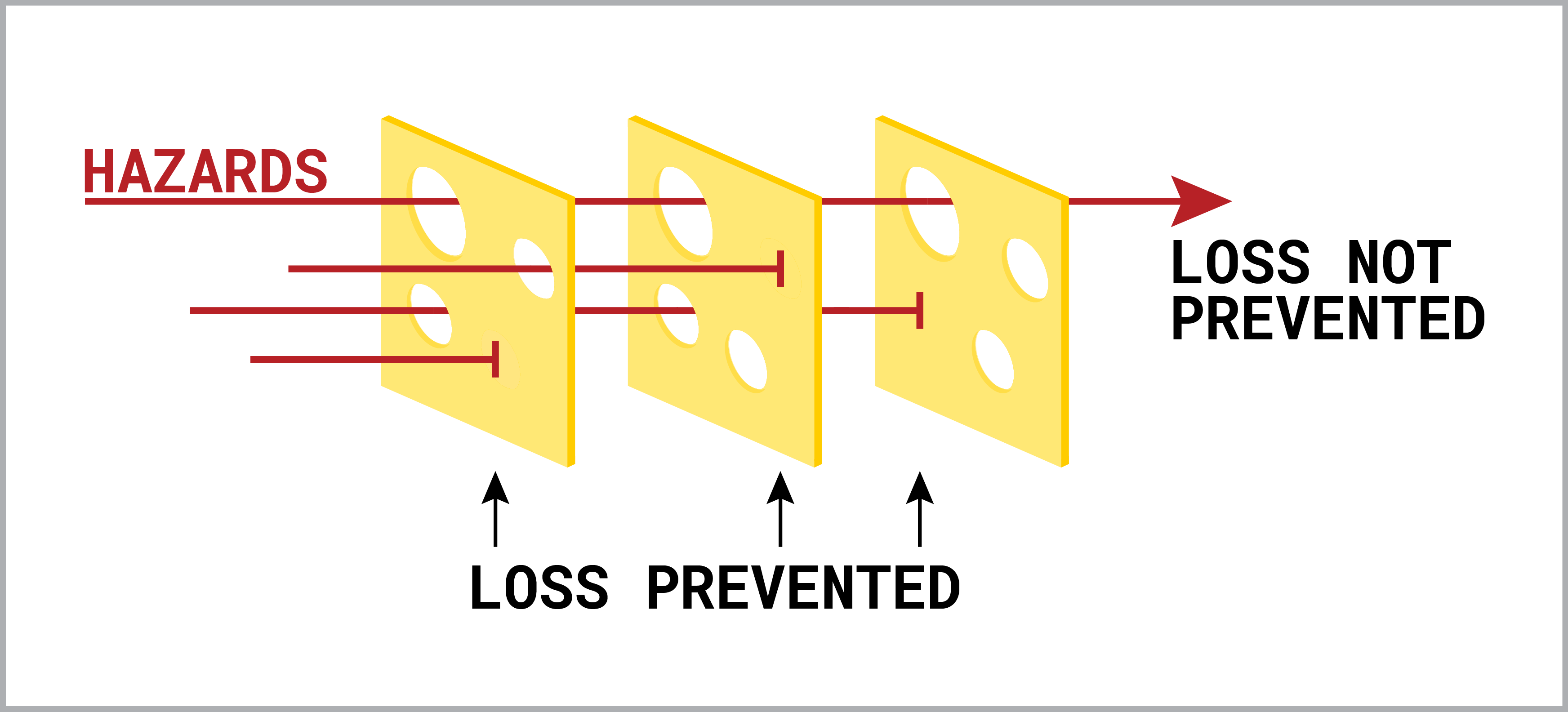

The Aviation Safety Industry's Swiss Cheese Model looks at Critical Control Points and works to identify the holes in the processes that could cause failures. Improving hand hygiene is critical to reducing cross contamination, so the goal is to minimize these holes and apply measures that encourage hand hygiene - even when no-one is looking. Below are 5 tips from our experience:

1. Educate and Motivate:

Education helps people understand both the "How" and the "Why".

Who taught you how to wash your hands? Do you use the right technique, and do you wash for the right amount of time? Educating people by actively demonstrating how to wash hands properly will allow them to do it right, or at least improve on what they did before. Take a few minutes to check out this video on how to wash hands correctly and see how your technique measures up. Do you have any missed spots?

At Saraya we can provide a number of options to help you, contact us and ask about our "Old McDonalds Farm" technique... trust us it works!

Provide reminders and references at critical points. Having "How To Use" instructions at the dispensers, to "Did you Miss A Spot?" posters in highly visible places reinforces the message. Check our poster options here.

Studies show that Peer Motivation is one of the most effective influences on people. Develop champions or influencers in the team who lead by example, and as leaders catch people doing it right and compliment them.

Create a culture of good Hand Hygiene. Everyone needs to do it right, every time, especially managers and leaders. See also the point on Hand Hygiene training during induction under our Procedures Tips below.

Explaining the Why

People respond well to the “Why” especially when they want to protect their colleagues, their customers, & their families - they may be the last gap in the swiss cheese preventing illness.

They may not have fully thought through the implications and the effects of an outbreak on the community, or a product recall on the company? Help them understand that washing hands is one of the most effective ways to reduce the risk of cross contamination.

2. Choose the Right Product

Do they Like the Product?

If they like to use it they will! If they dislike it…well it is unlikely they are going to use it when no-one is looking… Another hole in the cheese! Choose a product your team wants to use, that feels great, and that does not dry their hands. Ask your team, and if necessary, trial another product. Want to have Saraya set up a trial at your facility, click here and let us know.

If you are putting in the effort to increase compliance, make sure the product is also effective and meets your needs. Make sure the soap is capable of washing off the level of soiling on your staff hands without drying out the skin. Also, does the sanitiser dose enough to completely cover the hands and not just a tear drop on the palm? Too little is ineffective and puts another hole in the cheese. Read the label or manufacturers instructions to see what the actual effective dose is - some require 2-3 pumps to be effective and we all know this is unlikely to happen in real time in a busy workplace.

Reducing pathogens is the goal so choose a product that has the efficacy you need. Some products provide much higher efficacy rates such as Smart-San Instant Mist which has shown a 6 Log reduction in germs and bacteria (99.9999%). If you want to see how the log reduction affects germ reduction download our guide to log reductions here.

Also ensure the product is allergen free and complies with your food safety program ( HACCP, SQF, BRC, etc).

Did you know that using a foam soap can save you up to 45% of the water used compared to a liquid/lotion soap. A facility of say 100 people could save up to 20,000 liters of water, and when you use a readily biodegradable product, this can add up to a significant impact on the environment, and even on the bottom line.

Using warm water makes hand washing more comfortable and reduces staff avoidance. It is also required by the Australian New Zealand Food Standards Code. Hot water does not make much difference to the reduction of Pathogens – this needs the right product, dosed at the right amount, and the correct technique used.

Is the Dispenser Suitable?

We take the approach that if it is easy to manage it will be managed better, but some systems have higher risks. Sealed pods eliminate contamination, speed up replacement times, prevent the wrong soap being placed in the dispensers Bulk refillable dispensers have a very high risk of contamination making your soap dispenser the point contamination . Studies show that up to 1 in every 4 bulk filled hand soap dispensers are contaminated - you could have more bugs on your hands AFTER washing than before.

We take the approach that if it is easy to manage it will be managed better, but some systems have higher risks. Sealed pods eliminate contamination, speed up replacement times, prevent the wrong soap being placed in the dispensers Bulk refillable dispensers have a very high risk of contamination making your soap dispenser the point contamination . Studies show that up to 1 in every 4 bulk filled hand soap dispensers are contaminated - you could have more bugs on your hands AFTER washing than before.

Keeping to one type also helps reduce your inventory and eliminates mistakes and frustration. Having different soaps for different areas eg. Antibacterial soap for food production and a fragranced soap for the toilets may cause confusion. Are the dispensing options suitable and easy to use? Does it dose enough product to be effective, is it reliable, and would a manual or automatic dispenser work best for you? If you need help finding the right dispenser option let us know here.

Keeping to one type also helps reduce your inventory and eliminates mistakes and frustration. Having different soaps for different areas eg. Antibacterial soap for food production and a fragranced soap for the toilets may cause confusion. Are the dispensing options suitable and easy to use? Does it dose enough product to be effective, is it reliable, and would a manual or automatic dispenser work best for you? If you need help finding the right dispenser option let us know here.

3. Right Place

One of the most common reasons for people not washing hands is the inconvenience of the facilities, they are just too far away or in the wrong place. This can open up another hole in your swiss cheese safety barrier.

Aim to have hand wash / sanitiser stations where ever people need them. If it is too far to go to wash your hands it is more likely that it will not be done. Are there sufficient dispensers the amount of people needing them? Install as many dispensers as are needed so that people can have quick and easy access. Dispensers are relatively cheap so use as many as needed. The placement of dispensers can also encourage use, such as a hand sanitiser OUTSIDE the toilets in a common area – so people can be seen when they use it… or not…. Having hand sanitiser stations in common areas in the office or at lifts and stairwells also encourage use. If there are temporary use areas or limited wall space consider using mobile dispenser stands for hand sanitiser. We would be happy to help you choose the right places for your dispensers, contact us here and we will find a solution for you.

4. Always Available

Empty or broken dispensers are also high on the list of reasons for people not washing their hands – and yes this is far too common…

If your hand hygiene system does not have the capacity to last the day/shift add more dispensers. Also allocate someone to check and refill regularly. Make sure to have hand hygiene dispenser checks on the Pre-Op forms. Have day stock available for fast replacement, and make sure staff know where to find these replacements.

A broken dispenser puts another hole in your Swiss cheese. Choose a dispenser that is robust enough for your facility, and if you have high volume usage expect additional wear and tear, so keep a few spare dispensers on the shelf.

Talk to Saraya if you have very high volume requirements, we have systems available to cope with thousands of doses per day that cost way less then you think....

5. Procedures – CCP’s

We often find the procedures, training, and actual practice do not match and this can create confusion which leads to non conformance.

We often find the procedures, training, and actual practice do not match and this can create confusion which leads to non conformance.

Have a good look to make sure your training backs up the procedures in place. Procedures are often in place to support Critical Control Points so having clear directions and training that back these up will help.

Work with key Stakeholders in your team to make sure the procedures are practical and workable.

Is hand hygiene training part of your onboarding procedures? Setting expectations early and providing the correct training as part of on boarding will link in with Point number 1 to reinforce the importance of Hand hygiene. Ask Saraya how to set this up.

Finding good staff is challenging, and there is a skill shortage in food workers so you may be hiring new entrants to the industry. Ensuring every new member of staff is well educated in hand hygiene reduces your risk’s.

Re-Evaluate regularly.

Schedule time with your team or even ask your supplier to audit your hand hygiene compliance so you know what is and what is no longer working, then make the changes needed. (Want Saraya to Audit this for you, let us know) Desk top Audit based on volume. Use a theoretical number of hand hygiene episode’s per person per day, multiplied by the number of staff, then multiply this by the dosed volume, and again by the number of operational days in a month. Use this theoretical volume as a benchmark to measure the actual volume against. To make this easy, download our Worksheet Here to plug in your numbers.

Summary

Hand hygiene is just one part of an effective food safety plan that is key to preventing contamination and closing the hole in the cheese. The overall goal is to make hand hygiene easy for people to comply with, and by providing targeted training so they know what to do and how to do it. Providing effective products that people like and want to use, in places that are convenient, then people are more likely to do the right thing even if no one is around.

Hopefully, these ideas will help you block a few holes in the cheese. If you need additional support get in touch with us to see how we can help.